A computer vision system is integrated with the OrbiPlant® vertical farming system for quality control. It uses two cameras to capture color and depth images of plants on a conveyor belt. These images are analyzed using deep learning to assess plant health and growth by estimating leaf surface area and detecting discoloration. The results are presented to users through a web-based dashboard.

| Topic Fields | |

| Published | 2023 |

| Involved Institutes | |

| Project Type | ICNAP Research/Transfer Project |

| Result Type | |

| Responsibles |

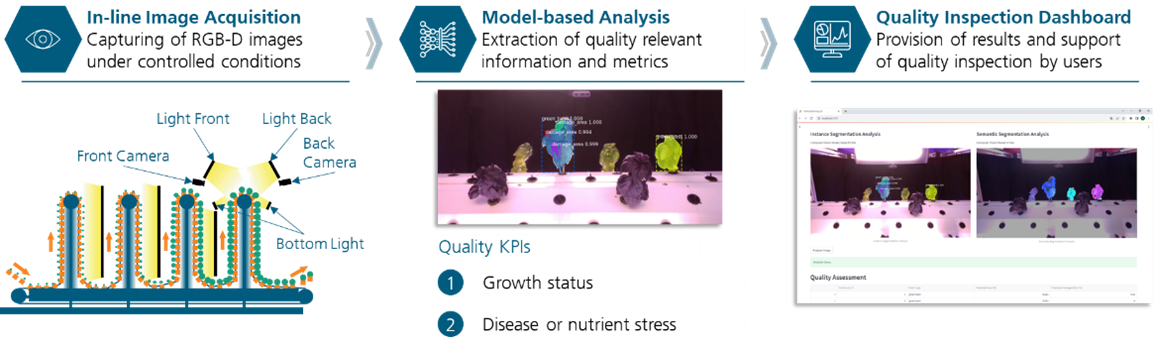

Vertical farming offers new opportunities for efficient and sustainable indoor production of plant-based foods. It requires continuous and non-destructive preharvest quality control to ensure high production quality. For this purpose, a computer vision-based system for crop quality control was developed based on the OrbiPlant® vertical farming system. Figure 1 depicts the structure of the developed system for visual quality control.

The system consists of two regular cameras mounted on top of the Orbiplant® loop structure that capture color and depth images of each individual row of plants from the front and back as they pass through the conveyor belt-driven system. The cameras are enclosed in a box with light sources to ensure reproducible lighting conditions. To simulate rejectable plant material, leaf area damage of the plants was induced by herbicide application. Recorded images are analyzed by deep learning models to extract and analyze relevant quality information. For each individual plant, an estimate of the leaf surface area is performed to evaluate the growth process against the plant population. In addition, discolored areas (e.g. due to disease or nutrient deficiencies) are detected and measured. The quality indicators are processed and made available to users in the form of a web-based dashboard for quality control with information on the position of the plant in the conveyor belt.

Contact us to get in touch! With a membership, you’ll gain full access to all project information and updates.

© Fraunhofer 2026